Workers building a new production line at the new General Dynamics factory in Mesquite, Texas. — ©️ 2024 The New York Times Company

IN a warehouse off Lyndon B. Johnson Freeway in an industrial area outside Dallas, Texas, the future of American military ammunition production is coming online.

Here, in the Pentagon’s first new major arms plant built since Russia invaded Ukraine, Turkish workers in orange hard hats are busy unpacking wood crates stenciled with the name Repkon, a defence company based in Istanbul, and assembling computer-controlled robots and lathes.

The factory will soon turn out about 30,000 steel shells every month for the 155mm howitzers that have become crucial to Ukraine’s war effort.

Ukraine fired 4,000 to 7,000 such shells daily for several months in 2023, according to Nato’s secretary-general, before infighting among US House Republicans held up further funding for Pentagon arms shipments. Large shipments of American artillery ammunition resumed in April after Congress passed an aid package that included US$61bil (RM288bil) to Ukraine.

The gap led to a drastic ammunition shortage for Kyiv, with Ukrainian troops able to fire only a fraction of the shells shot at them by Russian forces.

To keep Ukraine’s artillery crews supplied, the Pentagon set a production target last year of 100,000 shells per month by the end of 2025. Factories in Scranton and Wilkes-Barre, Pennsylvania, together make about 36,000 shells per month. The new General Dynamics facility in Mesquite, Texas, will make 30,000 each month once it reaches its full capacity.

The 100,000-per-month goal represents a nearly 10-fold increase in production from a few years ago.

An Ohio-based defence firm called IMT is expected to make up the difference.

Less than a year ago, the surrounding area in North Texas was just a dirt field. But with millions of dollars from Congress and help from Repkon, American defence firm General Dynamics was able to open the factory about 10 months after breaking ground.

“Despite all our starts and stops with the government, the continuing resolutions and getting the last supplemental, the industrial base responds when you fund it and it’s done right,” William LaPlante, the Pentagon’s top acquisition official, said in an interview with his Army counterpart, Douglas Bush.

According to LaPlante, the United States has provided more than three million 155mm shells to Ukraine since the war began in February 2022.

“When government and industry work together and Congress gives us sufficient latitude, we can still do great things in this country really fast,” Bush added.

Whether the increase in artillery ammunition production alone will be enough to change outcomes on the battlefield in Ukraine’s favour is, however, unknown.

“The steady increase of artillery ammunition production is significant for long-term US and Ukrainian needs,” said Michael Kofman, an expert on the Russian military and a senior fellow at the Carnegie Endowment for International Peace.

“But even in the best-case scenario, I would say those late-2025 output targets will arrive late in this war, and it is likely that Russian artillery output will still be higher than the US and Europe combined at that point,” he added.

“Let’s say a year and a half from now both the US and Europe are making, or buying, over a million shells each,” he said. “That’s still probably less than what Russia is going to produce this year.”

The Mesquite factory will consist of three production lines in different buildings – one of which will share space with a distribution centre for Frito-Lay that had a Cheetos-branded truck parked outside. When all three lines are completed, most of the Turkish workers will go home.

Half of the on-site American workforce came from another General Dynamics plant about 15km north in Garland, where the company forges steel casings for aerial bombs. The Mesquite factory will add about 350 jobs to the local economy when it reaches its full production capacity next year, company officials said.

Once complete, the empty shells made in Mesquite will be shipped to the US Army’s sole facility for filling them with explosives – a World War II-era plant in Burlington, Iowa. Next year, however, many of the shells will be sent to another new General Dynamics factory that is under construction in Camden, Arkansas.

The Pentagon’s drive to reinvest in ammunition production will also result in the Iowa plant opening a second line for filling shells with explosives and the partial reopening of a plant in Parsons, Kansas, for packing artillery propellant charges that was largely shuttered in a round of base closures in the 2000s.

Once complete, an unguided shell will be just under 1m long and weigh roughly 45kg – 11kg of which will be its explosive fill. That is enough to kill people within 30m of impact and cause injuries more than 130m away.

LaPlante and Bush both indicated that European countries were also ramping up their artillery ammunition production, and US defence contractors are in talks with the Ukrainian government to find ways to help Ukraine bolster its own domestic defence industry.

The United States has transferred sensitive manufacturing plans for more than 1,000 American weapons to Ukraine and translated an equal number of technical manuals from English to Ukrainian, the two officials said.

When asked, they stopped short of saying which weapons.

“What are they using the most?” Bush replied. — ©️2024 The New York Times Company

American arms industry capitalise

Artillery shells at various stages of production at the new General Dynamics artillery ammunition factory in Mesquite.

Artillery shells at various stages of production at the new General Dynamics artillery ammunition factory in Mesquite, Texas, on May 21, 2024. (Desiree Rios/The New York Times)

Workers assembling computer-driven robots and flow-forming machines at a new General Dynamics artillery ammunition factory in Mesquite.

Workers assembling computerdriven robots and flow-forming machines at a new General Dynamics artillery ammunition factory in Mesquite, Texas, on May 21, 2024. (Desiree Rios/The New York Times)

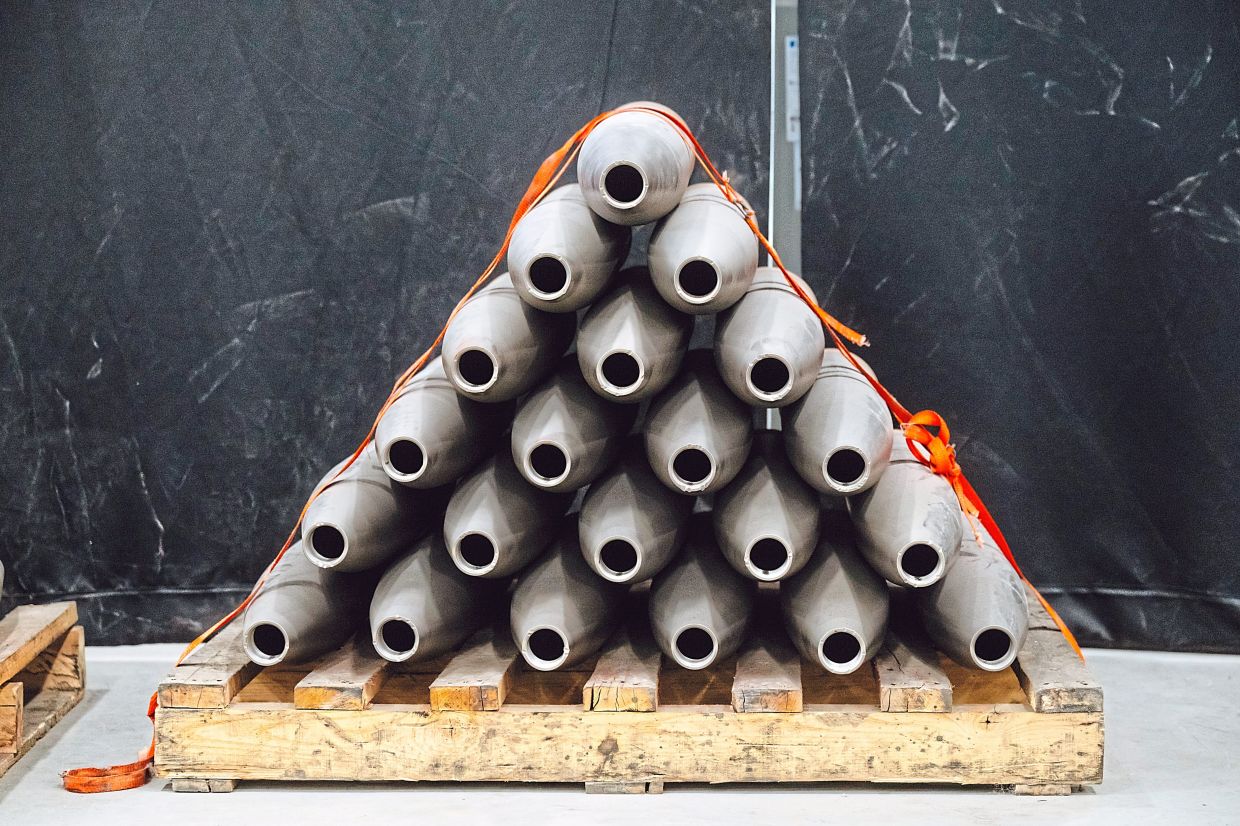

A stack of artillery projectile metal parts on the factory floor.

A stack of artillery projectile metal parts inside the new General Dynamics artillery ammunition factory in Mesquite, Texas, on May 21, 2024. (Desiree Rios/The New York Times)

Bins of parts awaiting assembly on the production line. — Photos: ©️ 2024 The New York Times Company

Bins of parts awaiting assembly inside the new General Dynamics artillery ammunition factory in Mesquite, Texas, on May 21, 2024. (Desiree Rios/The New York Times)

Stacked steel bars inside the new General Dynamics artillery ammunition factory.

Stacked steel bars inside the new General Dynamics artillery ammunition factory in Mesquite, Texas, on May 21, 2024. (Desiree Rios/The New York Times)